Unleashing Performance: The Innovative Clutches by WPT Power

Clutches are intricate mechanisms in vehicles and machinery that seamlessly couple and disconnect the driving force from the driven components. Grasping the multifaceted nature of clutches demands exploring the deeper mechanical principles governing torque transmission, friction management, and sturdiness. Fundamentally, clutches mediate power transfer via surface contact friction, merging two precisely crafted surfaces to transmit torque dependably. The meticulous designing and selection of interface materials—engineered to exacting standards—ascertain how competently a clutch can handle loads without slithering or overheating under duress. This refined coordination of pressing forces and friction exemplifies engineering ingenuity, transforming bare kinetic energy into purposeful motion and functionality through deft modulation.

The progression of clutch technology demonstrates advancements in the material sciences and mechanical engineering disciplines. Today’s clutches frequently highlight attributes like self-adjusting mechanisms, which optimize performance by ensuring suitable engagement across varying operating circumstances. Manufacturers have experimented with an assortment of materials ranging from organic compounds to carbon fiber composites, astutely stabilizing weight, strength, and heat endurance. Breakthroughs like hydraulic activators further magnify precision in regulating engagement timing, inevitably guiding to smoother vehicle operation. By delving into these mechanisms, one can appreciate the extensive thought—both theoretical and functional—that has gone into developing a component that appears simple yet plays an essential role in performance capabilities.

Distinct Types of Clutches: What Makes Each One Unique?

The landscape of clutch technology incorporates several types, each cleverly tailored for specific applications and performance benchmarks. Some of the most common forms consist of friction clutches, hydraulic clutches, magnetic clutches, and pneumatic clutches, all offering exclusive benefits and drawbacks tailored to their intended purpose. Friction clutches, for example, are prevalent in manual transmission vehicles because of their simplicity and efficacy in transmitting power. Their functionality relies on the friction produced between two surfaces, making them highly adaptable if in industrial equipment or automotive usages.

Hydraulic clutches differ noticeably; using hydraulic fluid rather than mechanical linkages gives these clutches an advantage in reliability and sleek operation. Automobiles outfitted with automated transmissions regularly include hydraulic methods, simplifying the driving experience while improving engagement accuracy. Meanwhile, electromagnetic clutches harness magnetic forces to engage and disengage. Their application regularly lends itself to situations where instant response is vital, such as in innovative automotive mechanisms. Lastly, pneumatic clutches, utilizing air pressure for engagement, find their specific niche in high-velocity applications where speedy cycling is preferred. Understanding these diverse styles provides helpful understandings into how engineers customize remedies to meet distinct demands within machinery evolution.

The relentless search for proficiency in machinery confirms that innovations in clutch layout stay at the leading edge of engineering analysis. In modern applications, the necessity for energy savings and operational proficiency has led to the integration of advanced clutches that offer higher reliability with lower weight and enhanced performance. Advancements such as dual-clutch mechanisms, popularized in high-performance automobiles, permit for seamless gear shifts by pre-selecting the next equipment in a way that decreases power loss. This engineering not only improves performance but also fuel efficiency, demonstrating how clutch developments can lead to significantly better operational metrics.

Moreover, advancements in electronic control systems have improved the ability to manage clutch engagements based on real-time conditions. Integrated sensors can adjust clutch applications on-the-fly, leading to optimized performance across varied situations, from heavy-duty vehicles traversing challenging terrains to ordinary passenger cars navigating crowded city streets. Smart clutches, equipped with sophisticated monitoring systems, can now predict wear and foresee necessary maintenance, allowing for proactive upkeep that lengthens component lifespan and reduces downtime. Such innovations in clutches are playing a vital role in driving forward the overall efficiency of machinery, as well as supporting progress on sustainability in energy usage and reductions in emissions.

Since its founding decades ago in the heart of America, WPT Power has upheld a legacy of outstanding engineering excellence, establishing itself as a leader in the mechanical components sector.

With origins rooted in a dedication to serve industries from agriculture to mining with premier drive solutions, WPT’s journey began through a commitment to quality that persists today. Over the years, the company has evolved by combining visionary leadership with close attention to the evolving demands of the market and dedicated research developing technologies ahead of current needs.

Throughout its history, WPT has proven adaptable to the ever-changing nature of manufacturing and engineering. Even during economic fluctuations, WPT updated product lines and enhanced existing technologies, continuing to strengthen its client relationships. The introduction of their pioneering Torque Limiter protected heavy machinery from potential damage during overloads, revolutionizing safety across sectors. As challenges arose in the industries it served, WPT stayed nimble by refining offerings tailored to dynamic needs—setting a new standard for competitors to match.

Key Innovations from WPT Power: Breaking Ground with Novel Clutch Design

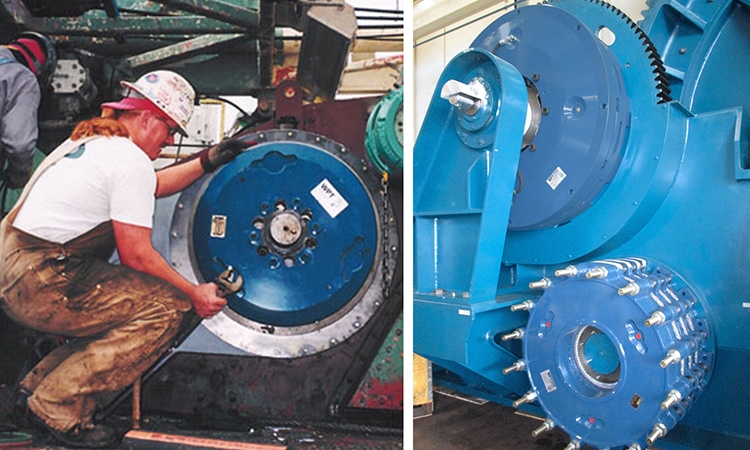

WPT Power’s spirit of progression is evident across an assortment of advanced solutions that broaden the boundaries of traditional clutch architecture. The company’s clutches feature one-of-a-kind engineering facets that substantially refine operational and functional efficiency. WPT Power’s patented clutches arrive outfitted with benefits such as abrupt release, dampness resistance, and easy-to-use installation mechanisms. These advances not only better performance but in addition improve durability and trustworthiness across diverse applications.

A noteworthy progression is the Heavy-Duty Clutch lineup, particularly engineered for rugged environments wherever reliability is paramount. With sophisticated materials that withstand wear and environmental harm, these clutches exemplify WPT’s commitment to strength under extreme conditions. Furthermore, their increasingly popular Power Take-Off (PTO) clutches allow users to engage machines devoid of stalling, an invaluable feature for industries that rely on continuous operation for productivity. By consistently investing in R&D and focusing on enhanced material properties, clutches by WPT Power remain a leader in the clutch manufacturing sector, setting benchmarks that others aspire to meet.

Client Inspiration: Real-World Applications of WPT Clutches

The true measure of WPT Power’s advances can best be illustrated through the success stories of its customers who implement these sophisticated clutches in diverse applications. For instance, in the agricultural sector, clutches by WPT Power are routinely utilized in high-horsepower tractors and combine harvesters, wherein the seamless engagement of power can mean the difference between a bountiful harvest and substantial losses due to machinery failure. Farmers report significant productivity increases attributed to the reliability and durability of WPT’s clutches, underscoring the practical impact these innovations have on day-to-day operations.

Similarly, across numerous industrial sectors where unyielding circumstances are commonplace, WPT’s clutch innovations have proven pivotal in maintaining consistent productivity levels while reducing repair expenses. Real-world perspectives from operators emphasize how WPT’s clutch remedies provide not just temporary benefits but long-lasting reliability and performance enhancements—a potent pairing in an industry where downtime can be extremely costly. Through these user experiences, clutches by WPT Power aid more than momentary demands but foster a continuous discussion that propels future progress, positioning the brand as a trusted ally across fields.

The Rewards of Progressing to WPT Power Clutches

Maximizing Apparatus Life: The Position of Premium Clutch Solutions

Committing to top-notch clutch remedies like those presented by WPT Power amplifies instant outputs—it’s regarding shielding and expanding the lifetime of critical machinery. Premium clutches are engineered to handle overload and high repetition rates, diminishing the wear and tear generally watched with regular parts in actuality. By incorporating WPT clutches, operators find themselves outfitted with products that not simply respond to demanding operational needs but additionally offer a resilience that significantly decreases the regularity of repairs and substitution expenses.

The advantages expand past only prolonging apparatus life; higher-quality parts better machinery’s all-around dependability, ultimately guiding to fewer unexpected breakdowns and smoother operation. Enhanced durability is complemented by more proficient torque transfer, resulting in lower fuel usage and operational costs—a proposition that resonates with companies eager to optimize spending while maximizing yield. By recognizing the intrinsic value of premium clutch solutions, businesses can create a substantial impact on their operational bottom line.

Performance Improvements: Why WPT Clutches Stand Apart

When evaluating upgrades for better performance, clutches by WPT Power deliver clear benefits distinguishing them from cheaper options. Their precise crafting facilitates more engaged and disengaged moments, leading to a smoother experience with improved control. This proficiency translates to quicker acceleration, shortened shifting periods, and most significantly, lessened power loss during transitions – pivotal for high-output applications.

Furthermore, as technology progresses and machinery grows increasingly sophisticated, the necessity for clutches compatible with advanced systems is paramount. WPT clutches frequently pioneer these requirements, featuring designs integrating with emissions standards while providing optimal power management. Users often remark on the heightened throttle response and overall feel of equipment outfitted with WPT Power clutches, a testimony to the company’s dedication to engineering excellence. These performance improvements speak straight to marketplace expectations, ensuring WPT remains interchangeable with high-quality, high-output solutions across industries.